Manufacturing Solutions, Powered by Additive Manufacturing

More capacity. More capability. Zero bottlenecks.

What We Do

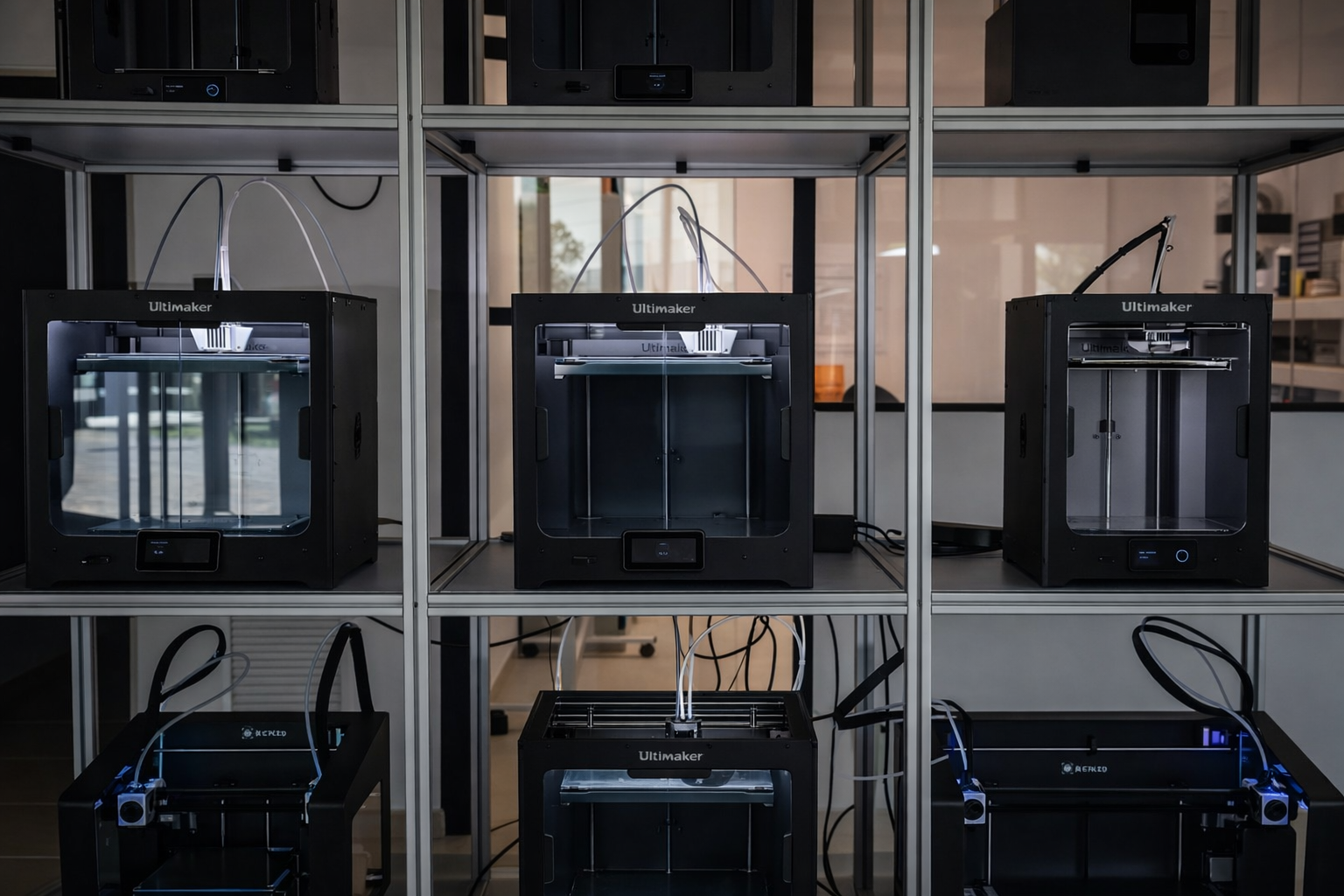

Production Capacity Without Overhead

K&M enables manufacturers to expand production and engineering capabilities through metal and engineering-grade polymer additive manufacturing without equipment investment. Our partner program provides on-demand additive capability with expert technical oversight, enabling faster lead times and expanded offerings without added operational complexity.

For manufacturers seeking to build additive manufacturing as an internal capability, K&M offers a structured Additive Training and Integration Package. We guide organizations through the implementation and scaling of metal and engineering-grade polymer additive manufacturing, covering application selection, process integration, and operational readiness to ensure additive manufacturing is adopted correctly and delivers a high ROI.

Training and Integration

Talk with a real person today (never an AI or chatbot) to see if we can provide value to your company.

Why Choose K&M

We deliver production-grade additive manufacturing for qualified applications, guided by deep industry expertise. With over 40 years of additive manufacturing experience informing every engagement, we apply selective redesign only when it is truly necessary to unlock performance, cost, or lead-time advantages. Manufacturers choose K&M because we are deliberately selective, pursuing only opportunities where additive manufacturing creates quantifiable value, and clearly advising when it does not to ensure time, capital, and engineering effort are never wasted.

Case Studies

Confidential Client

Industrial Parts Design and Manufacturer

Location: United States and South America

This client produced consumer goods for individuals, small businesses. They also developed corporate branding merchandise for select global businesses. They experienced logistics and supply chain difficulties in their US market, further complicated by tariffs. K&M stepped in, manufacturing their products and fulfilling orders from the US. This resulted in lower costs, simplified logistics and shorter lead times.

This client was looking for ways to lower cost on a piston component. K&M optimized the component for Additive Manufacturing and found the best Additive solution. This resulted in immediate cost reduction per part, resulting in a large profit increase for this high-volume product.

Confidential Client

Automotive Racing Equipment Manufacturer

Location: United States

Confidential Client

Consumer Goods Manufacturer

Location: Europe

We consult and provide advanced additive manufacturing capabilities to this customer. Parts produced included high volume rubber (TPU) plugs, and advanced polymer parts that were integrated into machined components. Without any upfront investment, this directly increased the client’s profit.